Our Industries

From the beginning, IPAC’s core business has always been fiberglass reinforcements for the Abrasive Industry. Over the years, IPAC’s precise cutting expertise over a wide array of materials has allowed the company to branch out to the Military, Healthcare, Automotive and Packaging Industries.

Bonded Abrasive

The company has focused on the bonded abrasives industry (i.e. grinding wheels, cut-off wheels) since 1959, and our name has become synonymous with quality, timely delivery and reliability. Today, IPAC is North America’s largest supplier of fiberglass reinforcements to the Abrasives Industry.

Military, Defense & Public Safety

IPAC’s Cutting and Kitting Capabilities for materials like Kevlar® and other aramids like carbon fiber, allow the company to service the every growing body armor industry for vests, helmets and other tactical gear. Contact IPAC for your next Cutting and Kitting job.

Healthcare

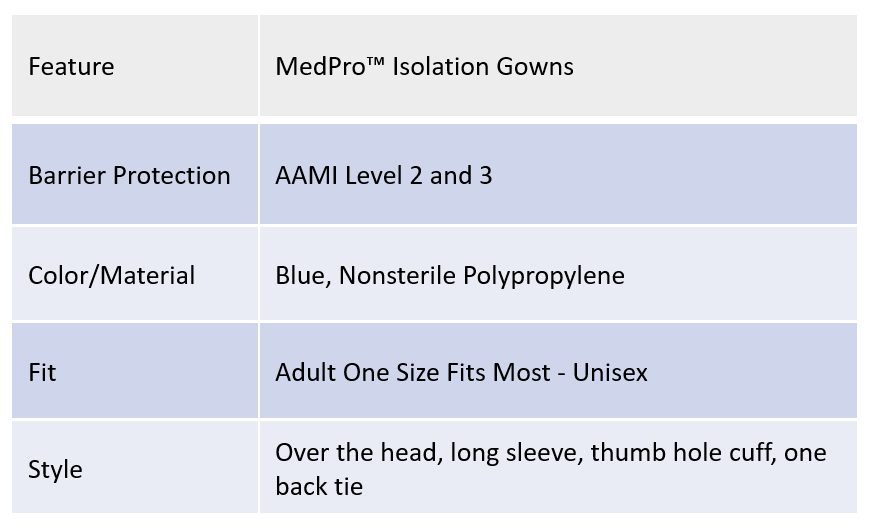

To answer the emergency call for PPE at the outset the COVID-19 Pandemic, IPAC put its specialty cutting skills to work producing Level-2-A and Level-3-A Isolation Gowns for our dedicated Healthcare workers in the spring of 2020.

IPAC’s MedPro™ family of Isolation Gowns meet the ANSI/AAMI PB-70 specifications for personal protective equipment. Providing protection with light weight but strong fabrics, IPAC’s MedPro gowns meet ASTM 5034 and ASTM 5733 for tensile strength and tear strength respectively.

Gowns are now available to the general public, click here to learn more about IPAC’s MedPro™ family of isolation gowns.

Automotive Aftermarket

IPAC’s polymer capabilities allow the company to design, manufacture and package specialty heat resistant, high temperature reinforced Tigerpatch® tape to the Automotive Aftermarket for exhaust pipe repair.

Packaging

Specialty Coating Services for foam used in the packaging industry are readily performed on customer supplied or IPAC designed materials. Contact IPAC for your next Coating project.